Description

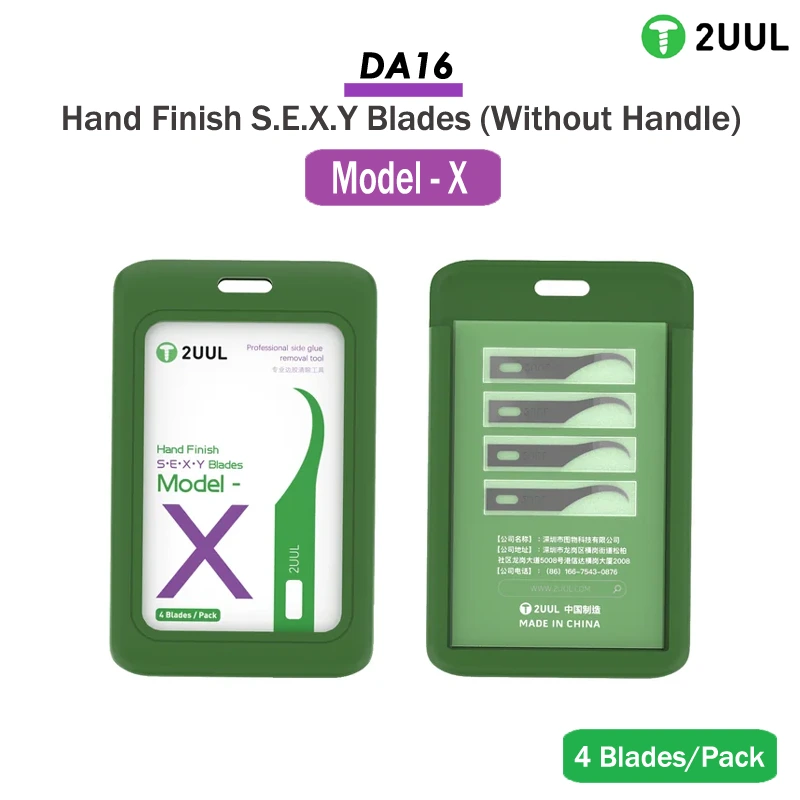

2UUL DA16 Precision Hand-Finish Blades – Model S (Pack of 4)

The 2UUL DA16 Model S Blade Set is an essential addition to any professional mobile repair toolkit, designed to meet the highest standards of precision, durability, and control. This pack includes four ultra-thin, hand-finished blades tailored for highly detailed and delicate repair work in the mobile phone, tablet, and micro-electronics repair industry. Unlike standard repair blades, these are handle-free, giving technicians the flexibility to use them with their preferred holders or custom handles for maximum comfort and accuracy.

Whether you are removing stubborn adhesive, cleaning underfill from around chips, separating IC components, or loosening screen edges, the 2UUL DA16 is engineered to handle it all with unmatched precision. Each blade is carefully shaped, polished, and finished to ensure smooth handling and long-lasting sharpness, making it a must-have tool for technicians who work on high-value devices and require absolute control during repairs.

Why Choose the 2UUL DA16 Model S Blade Set?

When it comes to mobile phone logic board repairs, especially at the micro-level, every move counts. Using the wrong blade can cause irreversible damage to delicate circuits or components. That’s why the 2UUL DA16 has been engineered with extreme care — from blade geometry to material selection — ensuring it delivers a perfect balance between strength, thinness, and safety.

These blades are not just thin; they are ultra-precise with a tip thickness of approximately 0.06 mm, enabling them to slip under tightly bonded layers without bending or breaking. This level of precision is especially valuable in BGA chip removal, NAND replacement, adhesive scraping, and fine detail work on PCBs.

Key Features of the 2UUL DA16 Model S Blades

1. Expertly Hand-Finished Edges

Every blade in the 2UUL DA16 set undergoes a meticulous polishing process to achieve a sharp yet smooth edge. This hand-finished touch ensures the blade maintains its sharpness longer and provides maximum control over each movement, especially in areas where a single slip could damage the motherboard.

2. Ultra-Thin, Tapered Tip for Extreme Precision

The tapered tip design, measuring just around 0.06 mm at the edge, allows the blade to navigate through extremely narrow spaces between components, adhesives, and protective layers. This thin profile ensures minimal disturbance to nearby parts during tasks like IC separation or glue removal.

3. Curved & Tapered Blade Shape

The combination of a slightly curved profile with a gradual taper makes these blades ideal for sliding underneath fragile parts without applying excessive force. This reduces the risk of PCB scratches, pad lifting, or component damage — a must for micro-soldering professionals.

4. Corrosion-Resistant Nano Coating

The rust-resistant finish not only improves the blade’s durability but also ensures smooth, snag-free movements. This is particularly important in high-humidity work environments or when working with heat during chip removal.

5. Multi-Purpose, Professional-Grade Use

While the 2UUL DA16 is perfect for IC and BGA chip removal, its thin yet strong structure also makes it ideal for:

-

Scraping hardened adhesive from motherboard surfaces

-

Cleaning underfill around CPU/NAND chips

-

Loosening screen or frame edges before separation

-

Micro-level prying during sensitive repair operations

Applications in Mobile Repair

The 2UUL DA16 blades are designed with the realities of mobile device repair in mind. Here’s how professionals typically use them:

-

IC or BGA Chip Removal – When replacing a CPU, GPU, or NAND chip, these blades can be used to gently lift the component after the solder has been reflowed.

-

Glue Layer Separation – Mobile manufacturers often use strong adhesives on screens, back glass, or between motherboard layers. The DA16 slides underneath to break the bond without tearing flex cables or damaging frames.

-

Underfill Cleaning – Many high-end devices have protective underfill resin around ICs, making removal tricky. The ultra-thin tip scrapes it away cleanly, preparing the board for re-installation.

-

Frame & Screen Edge Loosening – When performing display replacements, these blades can slip between glass and frame, loosening the bond before you use other separating tools.

-

Micro-Repair Detailing – From scraping corrosion to removing debris, these blades handle small clean-up jobs with precision.

Designed for Professionals Who Demand More

The 2UUL DA16 Model S Blade Set is not a beginner’s tool — it is built for experienced technicians who understand the delicate nature of motherboard and micro-component handling. In the hands of a skilled professional, it becomes a versatile, precision instrument capable of working in areas where standard blades are simply too thick or too inflexible.

Durability Meets Flexibility

Unlike cheaper blades that may warp or dull after a few uses, the 2UUL DA16 is designed for long-term performance. The combination of high-quality metal alloy, corrosion-resistant coating, and hand-finished edges ensures that every blade in the pack is both sharp and resilient.

The handle-free design means you can use the blade with various compatible holders or even create a custom handle for your preferred working angle. This adaptability gives technicians full control over their working style.

Care & Maintenance Tips for the 2UUL DA16

To keep your 2UUL DA16 blades performing at their best, follow these professional care guidelines:

-

Store Safely – Keep the blades in their original case or a protective sleeve to prevent accidental edge damage.

-

Avoid Excessive Force – These blades are extremely thin; let the sharpness do the work instead of applying pressure.

-

Clean After Use – Remove adhesive residue or flux after each use to maintain smooth operation.

-

Keep Dry – Even with corrosion resistance, always dry the blade after cleaning to ensure maximum lifespan.

Why the 2UUL DA16 Stands Out in the Market

There are many precision repair blades available, but few match the balance of thinness, strength, and control found in the 2UUL DA16 Model S. Whether you’re working on an iPhone logic board, a high-end Android motherboard, or performing micro-soldering work, this blade set delivers a level of performance trusted by professional repair technicians worldwide.

Final Thoughts

The 2UUL DA16 Precision Hand-Finish Blades – Model S (Pack of 4) is more than just another set of repair blades — it’s a precision-engineered tool designed for the demands of modern electronics repair. From IC lifting to adhesive scraping and frame separation, it provides the accuracy, safety, and durability required in high-risk repair environments.

If you want to take your repair capabilities to the next level, investing in the 2UUL DA16 will ensure you have the right tool for the most delicate jobs. Precision, durability, and control — that’s what makes the 2UUL DA16 the ultimate choice for expert mobile repair professionals.