Description

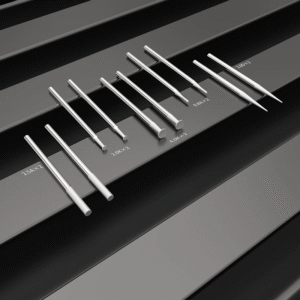

2UUL WL‑2015 Double‑Sided Desoldering Wick – High-Precision Copper Braid for Clean Solder Removal

When it comes to electronics repair and soldering work, the ability to cleanly and efficiently remove solder is essential. Without the right tool, desoldering can be messy, time-consuming, and risky for delicate components. The 2UUL WL‑2015 Desoldering Wick solves this problem by offering a high-quality copper braid with pre-applied flux, designed for precision solder removal in smartphones, laptops, and other PCB-based devices.

Engineered for technicians, engineers, and DIY electronics enthusiasts, this desoldering braid ensures smooth solder absorption, reduced heat exposure, and clean pad preparation. With its anti-oxidation coating and compact design, the 2UUL WL-2015 stands out as one of the most reliable desoldering wicks in the electronics industry.

What is a Desoldering Wick?

A desoldering wick (also known as solder braid) is a finely woven copper strip treated with flux, used to remove solder from circuit boards. When placed on a solder joint and heated with a soldering iron, molten solder is drawn into the braid through capillary action.

Unlike bulky suction pumps or vacuum tools, wicks allow for precise and controlled solder removal, making them especially useful for fine-pitch components, surface-mount devices (SMDs), and delicate repair work on modern electronics.

Technical Specifications of 2UUL WL-2015

-

Width: 2.0 mm

-

Length: 1.5 m spool

-

Weight: ~8 g

-

Material: High-purity copper braid

-

Flux: Pre-applied no-clean flux

-

Treatment: Anti-oxidation protection for durability

The 2.0 mm width makes it versatile for medium-sized solder pads, connectors, and multi-pin components, offering a balance of efficiency and precision.

Key Features of 2UUL WL-2015

1. Precision Width for Accurate Work

The 2.0 mm braid width is ideal for desoldering smartphone logic boards, laptop PCBs, and consumer electronic devices. It provides enough coverage for solder joints without damaging nearby traces.

2. Double-Sided Copper Braid

Made from oxygen-free copper strands, the braid delivers maximum solder absorption. The double-layered design ensures quick wicking action, reducing iron contact time and preventing PCB overheating.

3. Pre-Fluxed for Faster Flow

Each copper strand is pre-coated with non-corrosive, no-clean flux, allowing solder to flow easily into the braid. This ensures efficient solder removal, even with lead-free solder that has higher melting points.

4. Anti-Oxidation Protection

To maintain performance over time, the WL-2015 is treated with an anti-oxidation layer, preventing copper degradation. This guarantees consistent results, even after extended storage.

5. Compact & Lightweight Design

The 1.5 m spool weighs just 8 g, making it easy to store in toolkits and convenient for field technicians. Despite its small size, it provides multiple uses, making it cost-effective.

Benefits of Using 2UUL WL-2015

-

Cleaner PCB Pads – Leaves surfaces smooth and ready for rework.

-

Heat-Safe Operation – Requires less heat exposure, protecting sensitive ICs.

-

Efficient Performance – Absorbs solder quickly, saving time during repair.

-

Multi-Purpose Applications – Suitable for SMDs, BGAs, connectors, and IC replacements.

-

Long Shelf Life – Anti-oxidation coating keeps it effective over time.

Applications of 2UUL WL-2015

This professional-grade desoldering wick is widely used for:

-

PCB Rework & Repair: Cleaning pads, traces, and solder bridges.

-

BGA Reballing: Removing solder residues during chip replacement.

-

SMD Component Removal: Safely desoldering fine-pitch parts.

-

Connector & Header Work: Useful for desoldering multi-pin connectors.

-

Mobile & Laptop Repair: Essential for modern electronics repair tasks.

How to Use 2UUL WL-2015 Desoldering Wick

-

Place the Wick – Position the braid over the solder joint.

-

Apply Heat – Press a heated soldering iron on top of the braid.

-

Absorb the Solder – The molten solder will flow into the copper strands.

-

Trim the Used Section – Cut off the solder-filled portion of the braid.

-

Repeat as Needed – Continue until the pad is fully clean.

💡 Pro Tip: For best results, use a temperature-controlled soldering iron (350–400°C) to protect delicate components from overheating.

Why Technicians Prefer Wicks Over Other Methods

Compared to desoldering pumps or vacuum systems, a solder wick offers:

-

Better control in tight spaces.

-

Minimal residue left behind.

-

Greater efficiency for fine-pitch solder joints.

-

Lower cost and portability.

For high-precision work like smartphone and laptop repair, a wick is often the preferred solution.

Final Thoughts

The 2UUL WL-2015 Desoldering Wick is more than just a roll of copper braid—it’s a must-have tool for technicians who value accuracy, safety, and efficiency in electronic repairs. Its 2.0 mm width, pre-applied flux, and anti-oxidation protection make it the perfect choice for mobile repair specialists, PCB engineers, and electronics enthusiasts.

Compact, reliable, and designed for precision, the WL-2015 ensures that solder removal is fast, clean, and effective—making every repair project smoother and more professional.

👉 Upgrade your repair toolkit today with the 2UUL WL-2015 Desoldering Wick and experience the difference in soldering efficiency and precision.

2UUL WL‑2015, 2UUL WL‑2015, 2UUL WL‑2015, 2UUL WL‑2015, 2UUL WL‑2015, 2UUL WL‑2015