Description

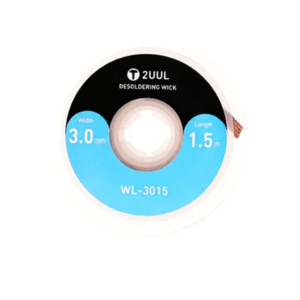

2UUL WL-1515 Double-Sided Desoldering Wick – 1.5 mm × 1.5 m Copper Braid for Precision Solder Removal

Introduction

In the world of electronics repair, precision and cleanliness can make the difference between a successful fix and a damaged circuit board. Whether you’re replacing smartphone ICs, cleaning solder pads on a motherboard, or repairing delicate electronic components, one tool that every technician needs is a reliable desoldering wick. The 2UUL WL-1515 Double-Sided Desoldering Wick has been engineered to deliver superior performance, offering professional technicians and electronics enthusiasts a fast, clean, and safe way to remove unwanted solder.

This product is more than just a copper braid; it’s a carefully designed solution that combines double-sided absorption technology, oxygen-free copper construction, and a flux-coated surface to make solder removal effortless. With a size of 1.5 mm width and 1.5 m length, it strikes the perfect balance between precision and practicality, making it suitable for mobile phone repairs, PCB maintenance, and general electronic rework.

What Makes a Desoldering Wick Essential?

A desoldering wick, sometimes called a solder braid, is a finely woven strip of copper that absorbs molten solder using capillary action. When placed on solder joints and heated with a soldering iron, the wick pulls in the liquid solder, leaving a clean pad or connection point behind.

The 2UUL WL-1515 takes this simple concept to the next level by offering:

-

Faster solder absorption.

-

Cleaner pad finishes.

-

Safer operation on delicate circuits.

For technicians who deal with smartphone motherboards, laptops, gaming consoles, or industrial PCBs, this tool is a game-changer.

Key Features of 2UUL WL-1515

1. Double-Sided Absorption Efficiency

Unlike traditional wicks that may only absorb solder on one side, the WL-1515 is engineered for dual-side absorption. This means it pulls solder faster, more evenly, and with less heat exposure to sensitive components.

2. Perfect Precision Size

-

Width: 1.5 mm – ideal for small pads, micro-soldering, and IC rework.

-

Length: 1.5 m – provides multiple uses for technicians handling frequent repairs.

The dimensions make it versatile, whether you’re repairing smartphones or desoldering medium-sized PCB components.

3. High-Grade Copper Braid

Crafted from oxygen-free pure copper, this wick offers excellent conductivity and heat transfer. The result is faster melting and quicker absorption of solder.

4. Flux-Coated for Enhanced Performance

Pre-treated with a no-clean flux coating, the WL-1515 eliminates the need for constant flux re-application. This prevents oxidation, enhances solder flow, and saves time during busy repair work.

5. Gentle on PCBs and Pads

Designed for safe use, the braid absorbs solder without damaging pads, traces, or components. It minimizes risks like lifted pads or burnt circuits that often occur with inferior wicks.

6. Cost-Effective and Long-Lasting

Each roll offers 1.5 m of braid, ensuring excellent value for technicians and repair shops. One roll can serve dozens of repair jobs, making it a smart investment for professionals.

Applications of the WL-1515 Desoldering Wick

This desoldering wick is built for versatility, covering a wide range of electronic repair tasks:

-

Mobile Phone Repairs – Cleaning solder pads during IC replacement, reballing, or connector installation.

-

PCB Rework – Removing solder bridges, excess solder, or cleaning damaged pads.

-

Micro-Soldering – Perfect for fine-pitch components, BGA chips, and SMD repairs.

-

Laptop & Gaming Console Repair – Restoring solder pads or removing faulty components.

-

DIY Electronics Projects – Essential for hobbyists working on Arduino, Raspberry Pi, or custom PCBs.

Advantages of Choosing 2UUL WL-1515

-

Professional-Grade Results: Leaves pads clean and ready for resoldering.

-

Time-Efficient: Absorbs solder quickly, reducing repair time.

-

Reliable: Built to withstand repeated heating cycles without falling apart.

-

Economical: One roll covers multiple projects, ensuring cost savings.

-

Safer Repairs: Reduces risks of overheating or damaging fragile circuits.

Why 2UUL WL-1515 Stands Out Against Generic Wicks

Many low-quality desoldering wicks suffer from problems such as poor solder absorption, weak braiding, or oxidation issues. The 2UUL WL-1515 sets itself apart with:

-

Uniform Copper Weaving for smooth solder flow.

-

Flux Pre-Coating that reduces the need for external flux.

-

Durability to withstand multiple soldering cycles.

-

Precision Size that balances versatility and control.

This makes it the preferred choice for repair professionals who cannot afford mistakes or inefficiencies during delicate repairs.

Best Practices for Using the WL-1515

To get the most out of your desoldering wick, follow these simple tips:

-

Place Wick First: Position the braid over the solder joint.

-

Apply Iron on Top: Heat the wick directly, not the PCB, to prevent damage.

-

Trim Used Sections: Cut off solder-saturated parts and expose fresh braid.

-

Use Proper Temperature: Maintain 350–380 °C for optimal results.

-

Apply Extra Flux if Needed: For stubborn solder, a little extra flux enhances absorption.

Who Should Use the WL-1515?

-

Mobile Repair Technicians – For iPhone, Samsung, and other smartphone repairs.

-

Electronics Engineers – For PCB prototyping and component replacement.

-

Repair Shops – Handling high volumes of rework tasks.

-

DIY Enthusiasts & Students – Learning soldering and desoldering techniques.

-

Industrial Repair Services – For large-scale PCB maintenance.

Value for Professional Repair Environments

Time and precision equal profit in professional repair centers. A tool like the WL-1515 ensures technicians work faster while delivering flawless results. Clean solder pads reduce the chance of errors, improving customer satisfaction and long-term reliability of repairs.

By using a high-performance wick like this, repair shops save money in the long run by avoiding rework, minimizing component damage, and maximizing technician efficiency.

Final Verdict

The 2UUL WL-1515 Double-Sided Desoldering Wick (1.5 mm × 1.5 m) is not just a simple repair accessory—it’s an essential tool for any technician or electronics enthusiast who values precision, safety, and efficiency.

With its dual-side absorption design, oxygen-free copper braid, flux coating, and optimized size, it delivers consistent, professional-grade results for a wide variety of repair tasks. Whether you are handling micro-soldering on smartphone motherboards, refurbishing PCBs, or working on larger electronic devices, the WL-1515 ensures that every job is completed cleanly and reliably.