Description

Introduction

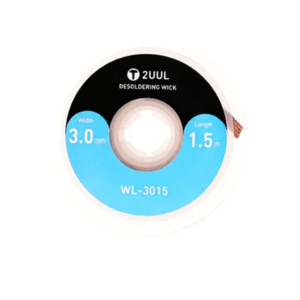

When working with electronics, mobile phones, or delicate PCBs, removing solder efficiently and cleanly is just as important as applying it. A poor-quality desoldering tool can leave behind solder residue, overheat components, or even damage circuit boards. To solve these challenges, 2UUL introduces the WL-2515 Double-Sided Copper Desoldering Wick, an essential tool designed to ensure precision, safety, and reliability in every repair.

This high-quality copper braid measures 2.5 mm wide and 1.5 m long, offering the perfect balance of surface area and length for a wide range of soldering and desoldering tasks. Whether you’re a professional mobile repair technician, an electronics engineer, or a hobbyist, the WL-2515 Desoldering Wick ensures that solder removal is fast, effective, and residue-free.

Why a Good Desoldering Wick Matters

In modern electronics, space is limited, and components are small. Incorrect solder removal can:

-

Overheat and damage PCBs.

-

Lift pads or traces due to excess heat or pressure.

-

Leave solder bridges, which cause short circuits.

-

Waste time and effort when low-quality braid fails to absorb solder properly.

The 2UUL WL-2515 Copper Wick is crafted with high-purity copper strands and an optimized weave that maximizes solder absorption while minimizing heat stress on delicate components.

Key Features of 2UUL WL-2515

1. Premium Copper Construction

Made from oxygen-free, high-purity copper, this braid provides excellent thermal conductivity, ensuring solder is absorbed quickly and efficiently.

2. Double-Sided Weaving

The advanced weaving pattern allows solder to flow smoothly into the braid from both sides, increasing absorption speed and efficiency.

3. Optimal Size (2.5 mm × 1.5 m)

-

2.5 mm width is ideal for medium-sized solder joints, connectors, and component pads.

-

1.5 m length provides enough material for multiple repair jobs, making it cost-effective.

4. Flux-Coated for Efficiency

Pre-coated with flux, the wick initiates fast solder absorption as soon as it touches molten solder, reducing the need for additional flux.

5. Precision Desoldering

Perfect for removing solder from:

-

Mobile phone PCBs.

-

Laptop and tablet motherboards.

-

Fine-pitch ICs and microchips.

-

Through-hole and surface-mount components.

6. Safe Heat Transfer

Because copper conducts heat evenly, the wick allows technicians to apply minimal heat while removing solder, protecting sensitive components from thermal damage.

Applications of WL-2515 in Repair Work

This desoldering wick is widely used in:

-

Mobile Phone Repair

-

Removing faulty charging ports.

-

Cleaning solder pads before IC reballing or replacement.

-

Absorbing excess solder during jumper wire work.

-

-

PCB Maintenance

-

Fixing bridges between solder pads.

-

Clearing solder-filled holes for component replacement.

-

Preparing clean pads for re-soldering.

-

-

Laptop & Tablet Service

-

Repairing damaged connectors.

-

Cleaning up old solder during component swaps.

-

-

General Electronics

-

Suitable for hobby electronics, prototyping, and circuit modifications.

-

How to Use the 2UUL WL-2515 Desoldering Wick

-

Place the Wick on the Joint – Position the braid directly over the solder to be removed.

-

Apply Heat with a Soldering Iron – Gently press the heated soldering iron tip onto the braid.

-

Absorb the Solder – The molten solder will flow into the braid quickly.

-

Lift and Trim – Once solder is absorbed, lift the wick and trim off the used section.

-

Repeat if Needed – Continue until the pad or joint is completely clean.

Advantages Over Ordinary Wicks

-

Faster absorption due to high-purity copper and double-sided weave.

-

Less flux requirement, thanks to pre-coating.

-

Reduced heat stress on components.

-

Consistent results, making it suitable for professional shops.

-

Durable length (1.5 m) for long-lasting use.

Why Choose 2UUL WL-2515 Desoldering Wick for Your Workshop?

-

Trusted Brand – 2UUL is known for delivering professional-grade repair tools for mobile technicians worldwide.

-

Perfect Size – 2.5 mm width is versatile for small to medium soldering tasks.

-

Professional Results – Ensures neat, clean pads, reducing chances of short circuits.

-

Cost-Effective – With 1.5 m length, it lasts through multiple repair jobs.

Tips for Best Results

-

Always use a temperature-controlled soldering iron to avoid overheating.

-

Trim the used portion of the braid after each use to maintain efficiency.

-

Store the wick in a dry, sealed container to prevent oxidation.

-

Use with quality soldering tools for maximum performance.

Who Can Benefit from WL-2515?

-

Professional repair technicians in mobile service centers.

-

Electronics engineers working on PCB development.

-

Hobbyists and learners practicing soldering skills.

-

Training institutes that teach soldering and desoldering.

Business Benefits of Stocking WL-2515

For repair businesses, using the right desoldering wick improves:

-

Work efficiency – quicker repairs mean more customers served.

-

Quality assurance – clean joints reduce returns and complaints.

-

Technician confidence – reliable tools make the job smoother.

-

Customer trust – high-quality repairs boost reputation.

Final Verdict

The 2UUL WL-2515 Double-Sided Copper Desoldering Wick (2.5 mm × 1.5 m) is an indispensable tool for anyone dealing with solder removal in mobile repair, PCB servicing, or electronics maintenance.

With its premium copper build, double-sided absorption, pre-flux coating, and optimal dimensions, this wick ensures fast, safe, and precise solder removal. Whether you are a professional technician or a beginner, the WL-2515 will make your desoldering work cleaner, easier, and more reliable.